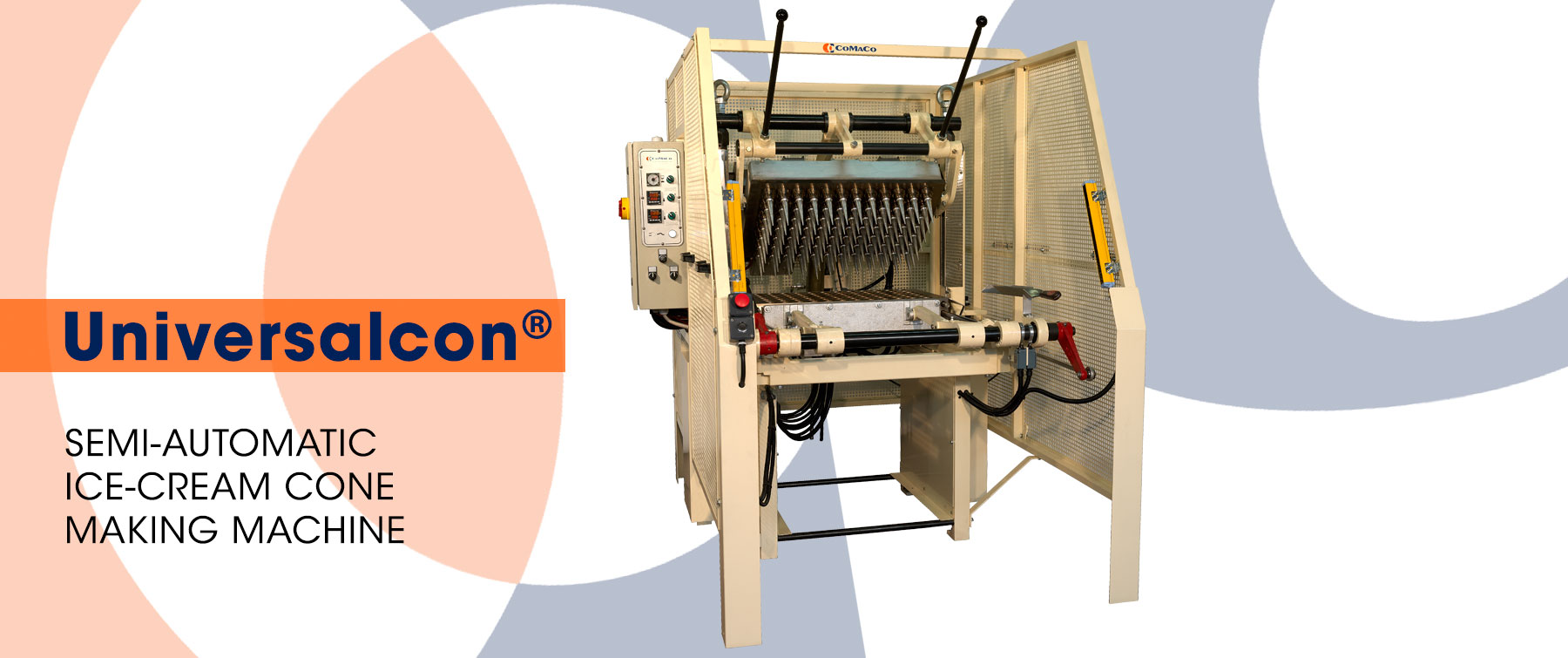

Semi-automatic machines for the production of ice cream moulded wafer cones and cups of any shape. The moulds have standard dimensions and are interchangeable. Heating can be by electricity (any voltage), natural gas or liquid gas. The capacity is from 1200 to 5500 pieces per hour.

The moulds can have 5, 6, 7, 8 or 9 rows. Automatic control of baking temperatures; the machine keeps the pre-set temperature and provides an acoustic and visible alarm at the end of the baking cycle. Opening and closing of the moulds by an automatic system controlled by the operator and actuated by pneumatic cylinders. The moulds are filled through a special feeding device; the dosimeter. Cones are automatically ejected into a container at the bottom of the machine when the lower mould is operated. The machines are supplied with all operative instructions including the recipe to make the wafer cones.